SER-SNR dust explosion isolation valve

SER-SNR dust explosion isolation valve

With the development of modern industry, the potential danger of dust explosions has greatly increased. In actual production, only using explosion-proof plates for explosion venting without proper explosion isolation can cause the flames and pressure waves generated by the explosion to be transmitted to other connected equipment through connected pipelines, leading to the occurrence of secondary or even more powerful explosions. Explosion proof technology can prevent explosions from spreading from the initial position to other process units, avoiding“second”The occurrence of explosions or system explosions to mitigate explosion disasters.Dust explosion isolation valve, as a passive device component, is used in situations that are prone to dust explosions and can be used for20District,21District and22Zone, can be used forClass ST1/ST2/ST3 (partial sizes)Organic and metallic dust.

The working principle is as follows:

Under normal operating conditions of the system, the internal throttle blade floats up due to airflow, and the explosion-proof valve opens; When the system is stopped, the throttle blade relies on the inclined end face on the inlet side due to its own weight; If detonation or explosion occurs on the outlet side of the explosion-proof valve under permissible conditions, due to an increase in back pressure, the airflow will flow in the opposite direction, causing the throttle blade to close. The pressure wave generated by the explosion will cause the throttle blade to tightly seal against the inclined end face on the inlet side, thereby preventing the explosion from spreading to upstream pipelines and equipment and providing isolation.

The characteristics of the Kangluoji ControlLOGIC SER-SNR explosion-proof valve:

1.Material: Carbon steel or stainless steel;

2. Kst value of large explosion indexUp to 300bar. m/s (ST1/ST2/ST3 dust)

3. Distance from dust collectorInstallation distance:2m(Size<=DN400), 3m(DN450<=Size<=DN1000);

4. Suitable for: sawdust, oxide dust, leather furniture dust, chemical dust, paper dust, food flour dust, fiber dust, inorganic dust, organic dust, metal dust, etc. (Size DN160-DN1000);

5.Enduring the maximum explosion pressurePred,maxValue:0.5bar(Size<=DN700),0.25bar(DN800<=Size<=DN1000);

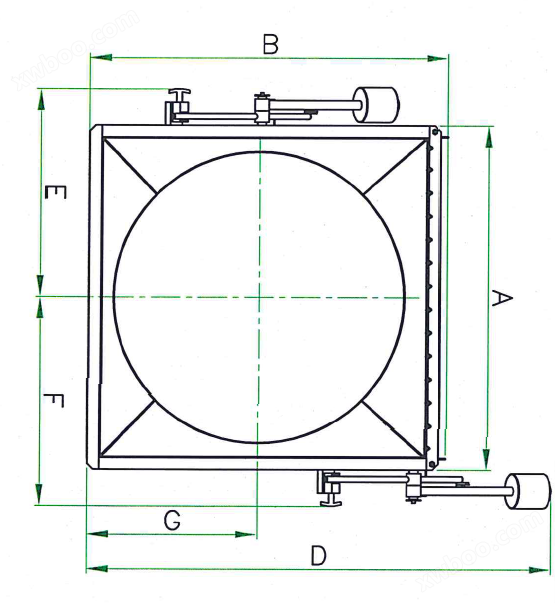

6. Sizes include: DN160, DN180, DN200, DN250, DN300, DN350, DN400,DN450,DN500,DN550, DN600,DN700, DN800, DN900,DN1000.

7. ATEX certification: EX IID

8. Can be equipped with position switches and dust accumulation sensors;

9. Horizontal installation, negative pressure system, unidirectional explosion-proof;

10. Equipped with self-locking mechanism to prevent backfire, safe and reliable.

11. Implementation standard: EN16447:2014

12. Origin: Italy.

SER-SNR dust explosion isolation valve

Application:Explosion-resistant(EEx d) explosion arrestment

In channels containing combustible dust, devices that can prevent flames from passing through, block waves, and dissipate waves are installed to control explosions within a certain range

Application case:

SER-SNR dust explosion isolation valve

SER-SNR dust explosion isolation valve